A few months ago, a homeowner in Baytown, TX, called McLeod Overhead Doors and Springs after his garage door jammed halfway during a storm. His garage door cables had frayed so badly that one finally snapped. The emergency repair cost twice what a routine maintenance visit would have, and could have been avoided altogether. Sadly, this story isn’t unique. Many property owners ignore the importance of regular garage door cable checks until a critical failure puts their safety or property at risk.

Nationwide statistics from the U.S. Consumer Product Safety Commission report over 20,000 garage door-related injuries annually, many stemming from failing garage door parts like springs, openers, and cables. These numbers highlight just how crucial it is to maintain the machinery that operates your garage door, especially the cables.

Garage door cables are more than just wires; they’re integral components of an entire engineered garage door system. They work with other garage door parts such as torsion springs, rollers, openers, and reinforcement brackets to lift, balance, and lower the door. If one cable fails, the entire system is compromised. That’s why regular maintenance and service checks from trusted providers like McLeod Overhead Doors and Springs are essential.

Understanding the Role of Garage Door Cables in Your System

Garage door cables are industrial-grade wires crafted from galvanized or stainless steel. Designed with precision engineering and manufactured through high-grade machining and fabrication, these cables work alongside torsion springs or extension springs to lift and lower the garage door evenly. Without them, the door becomes unstable and potentially dangerous.

Each garage door cable wraps around a drum, positioned above the door. When the garage door opener activates, it turns the drums, allowing the cables to wind or unwind and lift or lower the door with control and balance. These cables carry much of the door’s weight, preventing sudden drops that can cause injury or property damage.

Whether you’re using a residential operator accessory, commercial door system, or smart garage kit, these cables are crucial in safely moving heavy overhead doors. Garage door cables are involved in nearly every mechanical motion your door makes. They are part of an interconnected web of components, including garage door hinges, garage door springs, garage door windows, and garage door operator systems, that ensure the smooth and secure operation of your door.

Signs of Cable Damage You Shouldn’t Ignore

Garage door cables endure wear and tear from daily use, exposure to weather, and lack of routine maintenance. Spotting early warning signs can prevent sudden failures, injuries, and expensive repairs. Below are the most common signs you should watch for:

1. Visible Fraying or Kinking

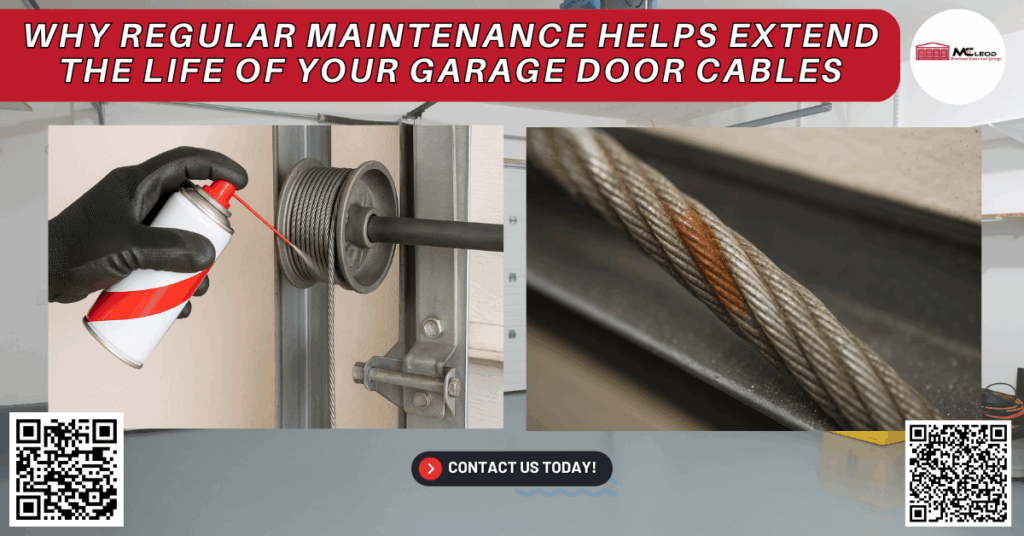

Inspect your cables regularly for frayed strands, kinks, or unraveling ends. These issues are early indicators that the cable’s strength is compromised. A frayed or kinked cable is far more likely to snap under tension, potentially causing serious damage or injury.

2. Corrosion or Rust

In humid, coastal areas like Baytown, salty air accelerates rust formation on metal components. Rusted cables lose structural integrity over time, making them prone to break without warning. Using galvanized or stainless steel cables and maintaining a dry environment helps extend their lifespan.

3. Unbalanced Door Movement

If your garage door opens unevenly, lifts faster on one side, or appears crooked when closed, this could signal a stretched or broken cable on one side. An unbalanced door doesn’t just look off, it puts unnecessary strain on the opener, rollers, and springs, often leading to further mechanical failures.

4. Unusual Noises During Operation

Pay attention to squeaking, grinding, or thudding noises. These sounds often point to cable tension issues, frayed strands catching on components, or misalignment. Noises are one of the earliest clues that something is wrong internally.

5. Slack or Loss of Tension

If cables appear slack or loose when the door is closed, the spring system or cable drum may be malfunctioning. This can cause the door to move jerkily or fail to operate entirely. Immediate inspection is necessary to prevent complete system failure.

Why Maintenance Is Critical to Cable Longevity

Regular maintenance isn’t just about keeping your garage door looking good; it’s about ensuring all its moving parts, especially the cables, remain in optimal working condition. Proper care leads to longer-lasting components, safer operation, and fewer unexpected repairs. Here’s why ongoing maintenance matters:

1. Prevents Emergency Breakdowns

Cables and torsion springs handle tremendous tension. When they fail without warning, the door can slam shut unexpectedly, posing a serious hazard. Routine inspections allow technicians to spot fraying cables, uneven tension, and weak points before they escalate into emergencies. Preventive maintenance minimizes the risk of sudden, dangerous malfunctions.

2. Prolongs the Life of All Garage Door Parts

Well-maintained cables keep your garage door balanced and running smoothly, reducing wear on other components like the springs, rollers, tracks, and opener. By minimizing unnecessary strain, you extend the lifespan of these parts and avoid the domino effect of failures that typically result from one neglected component.

3. Enhances Safety at Home and Work

Whether it’s your home garage, a workshop, or a commercial facility, safety is non-negotiable. Routine service ensures that your cables and related hardware meet operational standards, reducing the likelihood of accidents. Properly maintained cables help prevent doors from dropping unexpectedly, protecting family members, pets, staff, and valuable equipment.

4. Reduces Repair and Replacement Costs

Catching minor cable issues early saves you from major repair bills later. Replacing a single worn cable is far more affordable than replacing damaged springs, openers, or an entire door system. Regular maintenance acts as inexpensive protection against the high costs associated with breakdowns and property damage.

5. Boosts Energy Efficiency

Properly tensioned cables ensure your garage door seals tightly when closed. This improves insulation by keeping out drafts, moisture, and pests. When paired with quality weatherstripping and insulation, well-maintained cables contribute to better energy efficiency, which can help lower heating and cooling expenses year-round.

What’s Included in Professional Garage Door Cable Maintenance?

At McLeod Overhead Doors and Springs, our team follows a thorough, step-by-step maintenance protocol designed to protect both residential and commercial garage door systems. Professional maintenance ensures that your cables and the entire system they support remain safe, reliable, and efficient. Here’s what you can typically expect during a comprehensive cable maintenance service:

1. Visual and Manual Inspection

We perform a detailed examination of all key components, looking for early signs of wear, corrosion, fraying, or misalignment in the cables. In addition, we inspect related parts, including torsion and extension springs, hinges, brackets, rollers, and the garage door opener assembly. This hands-on approach helps detect small issues before they escalate into major failures.

2. Testing and Calibration

Our technicians use precision tools to assess the balance and tension of your cables, springs, and drums. Proper calibration ensures that the garage door opens and closes smoothly and remains level. This reduces unnecessary stress on the opener and prolongs the life of the entire system. This step is critical for both safety and longevity.

3. Lubrication of Moving Components

While the cables themselves should remain free of grease to avoid dirt buildup, we lubricate pulleys, hinges, rollers, and other moving parts with high-grade lubricants. This reduces friction, prevents premature wear, and keeps your garage door operating quietly and efficiently.

4. Tightening of Fasteners

Loose fasteners like lag bolts, screws, or brackets can lead to structural misalignment or even component failure. We ensure that all hardware, including reinforcement brackets, cable anchors, and track supports, is tightened and properly secured. This maintains the structural integrity of the garage door system and prevents vibration-related issues over time.

5. Safety System Checks

Safety is always a priority. We inspect garage door openers, auto-reverse sensors, manual release mechanisms, and any connected gate openers to ensure they function properly in an emergency. Our service also includes testing remotes, verifying backup battery systems, and confirming that operator controls comply with safety regulations.

What Causes Garage Door Cable Damage?

Understanding what leads to garage door cable damage helps you take preventative steps and extend the life of your entire door system. Several key factors contribute to premature cable wear and failure:

Salt and Humidity in Coastal Areas

In coastal regions like Baytown, high humidity and salty air accelerate the corrosion of metal components. Garage door cables, springs, and hardware are especially vulnerable to rust, which weakens the steel over time. Routine inspections and the use of corrosion-resistant materials can catch and prevent early-stage rust before it leads to dangerous breakage.

Improper Alignment

When garage door tracks are misaligned or torsion springs are not wound properly, the door’s weight is distributed unevenly. This uneven pressure causes one cable to wear faster than the other, leading to premature failure. Our technicians rely on precision calibration tools to ensure the door system is balanced, aligned, and functioning as designed.

Friction From Dirt and Debris

Dust, grime, and debris that collect in the tracks, rollers, and brackets increase friction on the cables. This friction causes additional tension and accelerates wear on the cable strands. Regular cleaning and proper lubrication of moving parts minimize this risk and help maintain smooth operation.

Heavy Use and Lack of Maintenance

Garage doors in busy households, commercial spaces, or manufacturing facilities often operate 10 to 20 cycles per day or more. This frequent use places greater strain on cables, springs, and related components. Without consistent maintenance, this wear can go unnoticed until it fails. Regular inspections and timely servicing help prevent unexpected breakdowns and extend the system’s lifespan.

Recommended Maintenance Schedule

So, how often should you maintain your garage door cables?

- Homeowners: Every 12 months, or every 6 months if your garage sees frequent use.

- Commercial properties: Quarterly inspections are recommended.

- High-humidity zones (like Baytown): Every 6 months due to faster corrosion rates.

This proactive approach ensures all garage door parts, especially the cables and garage door springs, are functioning properly throughout the year.

DIY vs. Professional Maintenance

It can be tempting to grab a wrench and inspect your garage door cables on your own. While simple visual inspections for fraying or rust are generally safe and recommended for homeowners, anything beyond that should be handled by a trained technician. Here’s why trusting the pros is the smarter, safer choice:

Tension Risks

Garage door cables and torsion springs are under extreme tension. Mishandling these components, even slightly, can cause them to snap with violent force. This can lead to severe injuries, property damage, or even death. Professionals understand how to safely manage, release, and reset this tension without putting themselves or your property at risk.

Specialized Tools Required

Proper maintenance and repairs require more than basic hand tools. Technicians use CNC-calibrated tension meters, alignment jigs, and specialized lift systems to achieve the precise calibration necessary for safe and reliable door operation. These precision tools ensure that tension is distributed evenly and that your system operates within the manufacturer’s specifications.

Warranties and Compliance

Repairs and adjustments completed by licensed professionals typically preserve your garage door manufacturer’s warranty. Attempting DIY repairs can not only void warranties but may also violate safety regulations or building codes. In commercial or rental properties, this can expose you to additional liability risks if something goes wrong after an unauthorized repair.

Frequently Asked Questions (FAQs)

Q1: Can I use regular wire or rope to temporarily replace a garage door cable?

No, garage door cables are made of high-tension steel designed for heavy loads—using substitutes like rope or non-rated wire is unsafe and can lead to serious injury or damage.

Q2: Do garage door cables need to be replaced when I get a new garage door opener?

Not necessarily, but it’s a good time to inspect them; if they show signs of wear, replacing them ensures optimal compatibility and performance with your new opener.

Q3: How much does it typically cost to replace garage door cables?

Garage door cable replacement usually costs between $150 and $250, depending on door type, labor, and whether additional components need adjustment.

Q4: What happens if only one of the garage door cables breaks?

If one cable breaks, the door can become lopsided and jam, putting uneven strain on the remaining components. Both cables should be inspected and likely replaced together.

Final Thoughts

Garage door cables may seem like minor parts, but they carry the burden of your entire door system every day. Their condition determines whether your garage door opens smoothly, stays aligned, and closes safely. Neglecting these essential garage door parts can lead to costly repairs, dangerous malfunctions, and premature system failure.

At McLeod Overhead Doors and Springs, we believe in delivering proactive, precision-based garage door services that prioritize longevity, safety, and performance. Our team is trained in the latest garage door technologies, using top-quality garage door parts, tools, and best practices in fabrication, engineering, and maintenance.

How Can McLeod Overhead Doors and Springs Help You?

At McLeod Overhead Doors and Springs, we provide more than just garage door service, we offer peace of mind. Serving Baytown, TX, and surrounding regions, we specialize in:

- Garage door cable replacement and maintenance

- Torsion spring and extension spring services

- Garage door opener repair and installation

- Custom door designs, installations, and hardware upgrades

- Commercial and residential garage door solutions

Our trained technicians use high-grade tools, compliant controls, and premium garage door products built for durability and performance. Whether you need annual maintenance or emergency repair, McLeod Overhead Doors and Springs is your trusted partner for garage door safety and efficiency.

📍 Address: 8820 N Hwy 146, Baytown, TX 77520

📞 Phone: (281) 603-2885

🔧 Call us today to schedule your cable inspection and keep your door systems running strong.